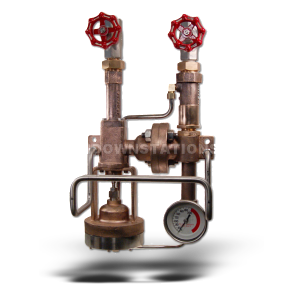

Low Pressure Steam Washdown Station – UP TO 60 PSIG

Model WD2010L (10-60 PSIG Steam Pressure)

- No Water – No Steam.

- 30-80 psig Water Pressure.

- 3 to 4.5 GPM

- 190°F Maximum Recommended Discharge Temp.

- Offered in both Bronze and Stainless Steel.

- Safe, low-maintenance Design.

Model WD2010L is a low pressure steam washdown station. It is ideal for those plants where hot water clean up is needed, but where only low pressure steam is available. It operates off steam pressure as low as 10 psig, such as waste steam. Steam and cold water are carefully and thoroughly mixed to provide “instant” hot water on demand. Using the proportional flow water and steam control valves, the operator can adjust the washdown station to deliver the desired hot water temperature as indicated on the dial thermometer located in the mixed water discharge. By depressing the ergonomically designed fail-safe trigger of the hand-held spray nozzle or the optional spray lance, the operator can direct a steady flow of hot water from a fine spray to a solid jet.

Washdown Stations are widely used in dairy, pharmaceutical, food processing, chemical and industrial plants. Wherever efficient, economical and low-maintenance means of hot-water clean-up is needed, Washdown Stations are used.

Features Include:

- Easy to maintain

- No carbonate build-up at steam inlet valve

- No special tool kits needed

- Manually operated flow proportioning control valves

- Internal steam and water check valves to prevent back-flow

- Integral steam-water venturi mixer for consistent mixing

- Discharge liquid temperature indicating dial gauge

- Simple wall mounting design and “mount-compatibility” for easy installation

- Discharge hose with swivel connections on each end

- Fail-safe trigger-actuated spray gun or shut-off lance

- Stainless steel hose rack for convenient hose storage

Dimensional Information

Available Models

| MODEL | DESCRIPTION |

| WD2010L-B-T | Bronze, steam & cold water wall mounted mixer-hose station. Includes globe valves, check valves, hose rack, mounting bracket, and adjustable angle temperature gauge. |

| WD2010L-B | Bronze, steam & cold water wall mounted mixer-hose station. Includes globe valves, check valves, hose rack, and mounting bracket. |

| WD2010L-S-T | 300 series stainless steel, steam & cold water wall mounted mixer-hose station. Includes globe valves, check valves, hose rack, mounting bracket, and adjustable angle temperature gauge. |

| WD2010L-S | 300 series stainless steel, steam & cold water wall mounted mixer-hose station. Includes globe valves, check valves, hose rack, and mounting bracket. |

Minimal Maintenance Required

Carbonate build-up at the steam inlet valve, a problem plaguing competitive units, is minimized. A check valve is optimally positioned within the mixing station between the steam inlet valve and the cold water chamber housing the specially designed steam-water venturi mixer. The steam valve seat is isolated from the cold water supply, preventing deposit of carbonates at the steam valve thus reducing the potential for steam inlet valve seizure. No special tool kits are required for the Washdown Station to operate at maximum efficiency and safety.

Safety First

When handling live steam, SAFETY COMES FIRST! To reduce the potential for steam discharge, our Steam/Water Washdown Stations employ a unique valve and diaphragm technology. Steam is automatically blocked from discharging from the mixing station using a specially engineered diaphragm device. The diaphragm uses the steam supply pressure to positively close the steam inlet valve to the mixing chamber. The mixing station does not rely on potentially unreliable components such as temperature sensors or electrical devices to keep the steam valve closed. The diaphragm device will permit the steam inlet valve to open only after sufficient cold water flow is established by squeezing the spray nozzle or lance. If at any time the cold water is restricted, the steam is automatically shut off. NO WATER-NO STEAM!